Production

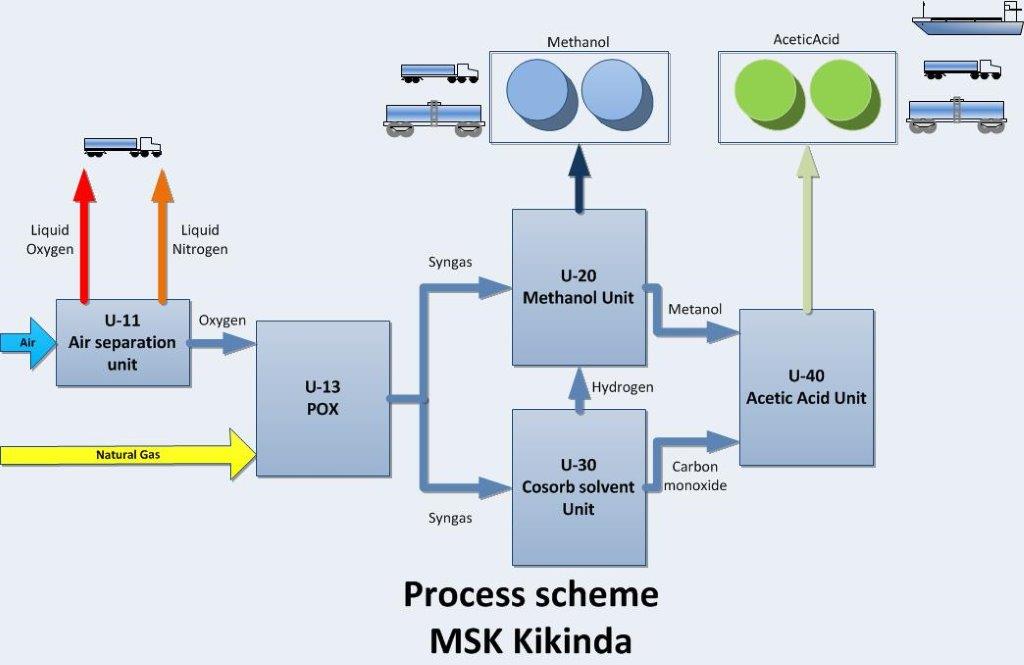

There are six production units in MSK the applied technologies are licensed. The name, technology and the capacity of production units are the following:

1. Air Separation Unit -ASU (oxygen and nitrogen production)

Capacity 19.000 Nm3/h of oxygen

Licence by L`air Liquide, France

Air Separation Unit is designed to produce gaseous oxygen of 99,5 % purity, gaseous nitrogen of medium pressure, as well as liquid nitrogen or liquid oxygen.

The air is compressed and cooled down in the plant to the temperature of about -185oC where it is then liquified and separated to oxygen and nitrogen. The oxygen in gaseous phase is compressed and sent to partial oxydation unit as a raw material for the production of synthesis gas.

Nitrogen from the unit is used for the inertization and blanketing vessels.

Liquid nitrogen is stored or can be used in production process as a gas, or sold at the market.

Input: air

product: oxygen, liquid oxygen, liquid nitrogen

2. Partial Oxydation Unit - POX (synthesis gas production)

Capacity 300.000 t/y

Licence by Texaco, U.S.A

Synthesis gas is obtained by the combustion of natural gas with the limited quantity of oxygen at temperature exceeding 1300oC. During the combustion, great heat quantity is released, and the obtained gas is cooled in water exchanger where high-pressure steam is generated.

Chemical reaction of synthesis gas generation is the following:

CH4 + ½ O2 → CO + 2H2

The steam generated in such a way is overheated in the Boiler house and then distributed in the system o for other production units.

After the purification, the cooled synthesis gas is distributed in two streams (flows) towards Methanol and Cosorb Unit.

Input raw material: natural gas and oxygen

product: synthesis gas, high pressure steam

3. Methanol Unit

Capacity 200.000 t/y

Licence by Johnson Matthey, England

The reaction of producing methanol is catalytic and is carried out between hydrogen - carbonmonoxide and carbon-dioxide in the reactor filled with solid catalyst.

Synthesis gas and hydrogen rich gas are mixed and under the pressure introduced in the reactor where crude methanol is produced.

The chemistry of methanol production is the following:

CO + CO2 + 5H2 → 2CH3OH + H2O

The methanol produced in such a way is then refined in distillation section where refined methanol of high quality is produced, which is as a product stored in the tanks for sales, while one part is used for Acetic Acid Unit.

Input raw material: synthesis gas and hydrogen rich gas

product: refined methanol (CH3OH)

4. COSORB Unit (Carbon monoxide Production)

Capacity 55.000 t/y

Licence by KTI, Netherlands

The purpose of Cosorb unit is to remove carbon-monoxide from the part of synthesis gas produced in partial oxydation unit. Carbon-monoxide is absorbed through the liquid catalyst from synthesis gas, which is later removed from the complex by desorption. After compression, that gas is sent by pipelines to acetic acid unit. The syngas without CO is a hydrogen rich gas which is then returned to methanol unit.

Input raw material: synthesis gas

product: carbon- monoxide (CO) and hydrogen rich gas

5. Acetic Acid Unit

Capacity 100.000 t/y

Licence by BP, England

The process of Acetic Acid production is based on the reaction of methanol and carbon-monoxide in the liquid phase with rodium complex as a catalyst and methyl-iodide as a promoter

Chemical reaction of Acetic Acid production:

CH3OH + CO → CH3COOH

The reaction of synthesis (carbonylation) is proceeding in the reactor, under the pressure and temperature and the product is raw acetic acid which is then sent to distilation section, where high-purity acetic acid is obtained, which is stored in tanks and sold at the market.

Input raw material: refined methanol (CH3OH), carbon-monoxide (CO)

product: Glacial Acetic Acid (CH3COOH)

6. Utilities Production Unit (demineralized water, water steam etc)

Input raw material: water

product: demineralized water, steam for production units

This unit produces steam of various pressures needed for the operation of production units

Demineralized water is produced by the purification of raw water, it is necessary for the operation of boiler house producing steam for production units.

By the finishing operation of steam from partial oxydation process, greater efficiency in the use of natural gas in all production units is achieved.

Laboratory

MSK laboratory performs physical and chemical testings of the following:

- CHEMICALS / RAW MATERIALS - RECEIVING CONTROL

- SAMPLES FROM THE PRODUCTION PROCESS - INTERPHASE CONTROL

- FINISHED PRODUCTS - FINAL CONTROL

Methanol analyses

Acetic Acid analyses

The laboratory is equipped with modern and various equipment (gas chromatographs, spectrophotometers, atomic absorption spectrophotometer, titration systems) and employees, skilled personnel assuring high-quality performance of laboratory testing services.